One-way damper: What is one-way damper? Longji plastic answers for you

Release time:

2020-04-16 14:00

Source:

Damper is a device that provides movement resistance and consumes movement energy. Using damping to absorb energy and reduce impact is not a new technology. In the aerospace, aviation, military, automotive, and other industries, various dampers (or shock absorbers) have been used to damp and dissipate energy. Since the 1970 s, people have gradually transferred these technologies to structural projects such as buildings, bridges and railways, and their development has been very rapid. Especially in the hydraulic viscous damper, which has a history of more than 50 years, before it was accepted by the American structural engineering community, especially during the long earthquake process, a lot of experiments, rigorous review and repeated demonstration tests have been carried out.

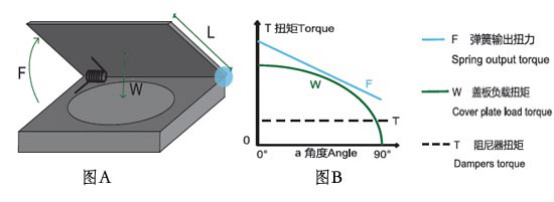

One-way damper is a device that can quickly stop the movable part of the instrument in a stable deflection position. In seismic instrumentation, one-way dampers are used to absorb the inherent vibration energy of a vibrating system, and their damping force is usually proportional to the speed of the vibrating system. One-way damper There are three main types of liquid dampers, one-way damper gas damper and electromagnetic damper. One-way dampers play an important role in compensating for small friction and air resistance in the vibration sensor pendulum system and improving the frequency response.

Various frictions and other obstacles that weaken free vibration are called damping. One-way damper "Special" components placed on the structural system can provide movement resistance and consume movement energy. We call them one-way dampers. A one-way damper is also called a damping device. A device that increases damping so that the vibration generated during impact is quickly attenuated. An ideal one-way damper is an oil damper. Commonly used one-way damper oils include silicone oil, grate oil, mechanical oil, diesel oil, engine oil and transformer oil, which can be made into plate type, piston type, square cone, cone, etc. Others include solid viscous dampers, air dampers and friction dampers. One-way damper According to the actual needs of vibration isolation design, damping ratio D = 0.05~0.2 is preferred.

and above are the relevant information about one-way dampers compiled by Dongguan Longji Plastic Electronics . If you need one-way damper , gear damper , damping gear and other products, please contact us.

Related News

Understanding One-Way Rotary Dampers: Essential Components for Engineering Machinery

--- One-way rotary dampers are specialized mechanical devices designed to control the speed and motion of rotating parts in various applications, particularly in the engineering and construction machinery sector. These dampers provide a critical function by allowing rotation in one direction while resisting it in the opposite direction. This unique characteristic makes them indispensable in ensuri

Exploring the Benefits of Two-Way Rotary Dampers in Manufacturing Processes

Exploring the Benefits of Two-Way Rotary Dampers in Manufacturing Processes Table of Contents Introduction to Two-Way Rotary Dampers What Are Two-Way Rotary Dampers? Benefits of Using Two-Way Rotary Dampers 1. Efficiency Enhancement 2. Vibration Reduction 3. Wear and Tear Reduction 4. Customization and Versatility 5.

The Importance of an Intelligent Bidet Lid Damper in Engineering and Construction Equipment

In the realm of engineering and construction machinery, attention to detail in every component can significantly impact overall performance and user satisfaction. One such component that has garnered attention in recent years is the intelligent bidet lid damper. While it may initially seem unrelated to heavy machinery, the principles behind its design and functionality can offer insights into impr

Guidelines for Choosing the Correct Rotary Damper for Sensor Toilets

Guidelines for Choosing the Correct Rotary Damper for Sensor Toilets Table of Contents Understanding Rotary Dampers The Importance of Rotary Dampers in Sensor Toilets Types of Rotary Dampers Factors to Consider When Choosing a Rotary Damper The Installation Process of Rotary Dampers Maintenance Tips for Rotary Dampers in Sensor Toilets Common Issues and Solutions C

Understanding Unidirectional Small Outer Diameter Dampers in Engineering Machinery

Unidirectional small outer diameter dampers are critical components used in various engineering and construction machinery applications. These dampers are specifically designed to absorb and dissipate energy from vibrations and shocks, ensuring the smooth operation of machinery while minimizing wear and tear on vital parts. Their small outer diameter makes them particularly suitable for applicatio

Understanding the Mechanism of 360-Degree Rotating Disc Dampers in Engineering Machinery

Understanding the Mechanism of 360-Degree Rotating Disc Dampers in Engineering Machinery Table of Contents 1. Introduction to 360-Degree Rotating Disc Dampers 2. Mechanical Principles Behind 360-Degree Rotating Disc Dampers 2.1 Key Design Features 2.2 Motion Concepts in Dampening 3. Applications in Engineering and Construction